How Membrane Switches Are Used in Medical Devices and Equipment

How Membrane Switches Are Used in Medical Devices and Equipment

Blog Article

Discover How Membrane Switches Function and Their Function in Modern Electronics

Membrane Switches stand for a sophisticated combination of innovation and style within the realm of contemporary electronics, offering as essential user interfaces in countless devices. Included several layers, these switches use pressure-sensitive devices to help with user communication. Their applications cover different industries, from customer electronics to clinical devices, highlighting their versatility and importance. Recognizing the complexities of Membrane button capability and their broader effects in boosting individual experience invites further exploration right into their design, benefits, and the cutting-edge growths forming their future in technology.

What Are Membrane Buttons?

Membrane buttons are distinguished by their sturdiness and resistance to ecological variables, such as dust, wetness, and extreme temperature levels. They can be tailored with numerous graphics, shades, and responsive responses alternatives, boosting customer experience while keeping visual allure - membrane switches. The consolidation of published circuits permits for seamless integration into devices, improving general performance.

The adaptability of Membrane switches is apparent in their capacity to support both complicated and simple control functions. They can integrate features such as LED indications and touch-sensitive innovation, accommodating certain individual requirements. As technology remains to advance, Membrane Switches remain vital for allowing effective and instinctive interface, consequently playing a critical duty in the innovation of modern-day electronic gadgets.

Components of Membrane Buttons

Membrane buttons are made up of several vital parts that interact to produce a trustworthy and practical user interface. The main elements consist of the graphic overlay, sticky layer, spacer layer, and conductive traces.

The graphic overlay functions as the interface, usually printed on an adaptable substratum such as polyester or polycarbonate. This layer not just provides aesthetic charm yet also includes responsive feedback, visual cues, and safety functions. Beneath the graphic overlay exists the adhesive layer, which safeguards the switch to the tool and guarantees resilience against ecological stresses.

The spacer layer is crucial for preserving the needed space in between the graphic overlay and the circuit layer. When stress is used, this void permits for the activation of the switch. The conductive traces, typically made from silver or carbon, develop the electric paths that finish the circuit when the button is engaged.

Additionally, a support layer may be consisted of for structural assistance and insulation. These parts team up perfectly, making certain that Membrane buttons are both straightforward and durable, making them essential in different modern digital applications.

Exactly How Membrane Switches Job

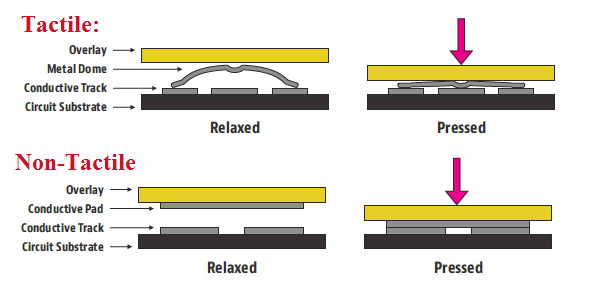

Just how do Membrane Switches feature effectively within electronic gadgets? Membrane Switches operate the principles of pressure-sensitive technology, utilizing a split building that includes graphic overlays, glue layers, and conductive aspects. When a user applies stress to the button, the top layer warps, allowing the conductive components underneath to make get in touch with and finish an electric circuit. This action causes the wanted feature within the device.

The layout of Membrane switches is critical for their effective procedure (membrane switches). The layers are thoroughly crafted to give responsive comments, resilience, and resistance to ecological elements such as dampness and dirt. The addition of domes-- little, raised locations within the switch-- boosts tactile feedback, supplying users with a visible click experience upon activation

Moreover, Membrane buttons can be customized in regards to size, form, and graphics, my link making them ideal for various applications. They are typically made use of in control panels, medical tools, and consumer electronics as a result of their sleek layout and integrity. Overall, the effective performance of Membrane buttons is essential in enhancing customer communication and ensuring seamless operation in contemporary electronic tools.

Applications in Modern Devices

Utilizing their special design and capability, Membrane buttons have actually that site become indispensable elements in a variety of modern-day digital devices. These functional user interfaces are utilized in customer electronic devices, industrial devices, clinical gadgets, and vehicle controls, offering seamless user communication.

In customer electronic devices, Membrane switches are commonly found in devices like microwaves, cleaning devices, and various other home devices, where they allow user-friendly control with a smooth profile. Their low-profile style facilitates integration into small gadgets, enhancing aesthetic allure without endangering performance.

In industrial applications, Membrane Switches function as control board for machinery, supplying resilience and resistance to harsh atmospheres. Their capacity to withstand moisture and contaminants makes them perfect for use in production and handling industries.

Medical tools likewise take advantage of Membrane buttons, which are designed to be easy to clean and preserve, guaranteeing hygiene in clinical setups. They are commonly utilized in analysis tools, client monitoring systems, and mobile clinical gadgets, where dependability is extremely important.

Benefits of Membrane Buttons

Among the vital benefits of Membrane switches is their adaptability, which enables them to be tailored for a selection of applications across multiple sectors. These buttons can be created in numerous sizes and shapes, accommodating distinct item demands while supplying seamless integration right into devices. Their thin profile makes it possible for a compact and smooth layout, often boosting the visual allure of electronic items.

An additional substantial advantage is their durability - membrane switches. Membrane buttons are commonly resistant to dust, wetness, and chemicals, making them perfect for rough atmospheres. This strength expands their life expectancy compared to standard mechanical buttons, lowering the find out here now need for constant replacements

In addition, Membrane Switches offer cost-effectiveness. The production process entails printing innovations that minimize production prices, particularly for big runs. This affordability, integrated with reduced upkeep needs, makes them an attractive option for suppliers.

Verdict

In verdict, Membrane Switches stand for a substantial improvement in individual interface technology within modern-day electronic devices. As the demand for resistant and user-friendly user interfaces continues to grow, the function of Membrane switches in shaping user experience will certainly broaden.

Membrane Switches represent an advanced integration of innovation and design within the realm of modern electronic devices, offering as essential user interfaces in various tools.In the realm of modern electronics, Membrane Switches offer as critical components that assist in customer communication with gadgets. As technology continues to progress, Membrane Switches continue to be important for enabling user-friendly and reliable user interfaces, thus playing a crucial function in the development of contemporary electronic gadgets.

Just how do Membrane Switches function successfully within electronic gadgets? Generally, the efficient functioning of Membrane buttons is crucial in enhancing individual interaction and making sure seamless procedure in modern-day electronic tools.

Report this page